オイルシールの取り付け – ステップバイステップ

オイルシール取り付け前

オイル シールは、欠陥や変形がないことを確認するために徹底的に検査する必要があります。外径に非常に小さな傷があると、シールの漏れの原因になります。ボアを評価して、摩耗や残留物がないことを確認します。初回運転時にリップ保護を確実にするために、シールとシャフトに潤滑油を塗る必要があります。

インストール方法

回転軸シールを取り付ける際には、適切なかみ合いを容易にし、シールのコックの可能性を減らすために、オイル シール取り付けツールの使用をお勧めします。圧入ツール (できれば空気圧または油圧プレス) を使用する場合は、ツールの外径がボアのサイズより 0.01 インチ (0.25 mm) 小さいことを確認してください。

シールコッキング:

シールコックとは、シールリップの片側でシャフトの干渉が大きくなり、オイルシールの機能に悪影響を与える可能性がある状態です。これにより、発熱量が増加し、シールリップが硬化して割れることがあります。最悪の場合、スプリングがシールリップから外れてしまうこともあります。

跳ね返ります:

ゴムで覆われた OD を使用すると、シールが取り付け後に跳ね返る場合があります。シールのゴム OD とボアが摩擦を生じ、押し込んだ後にシールが取り付けポイントから抜けてしまう可能性があります。

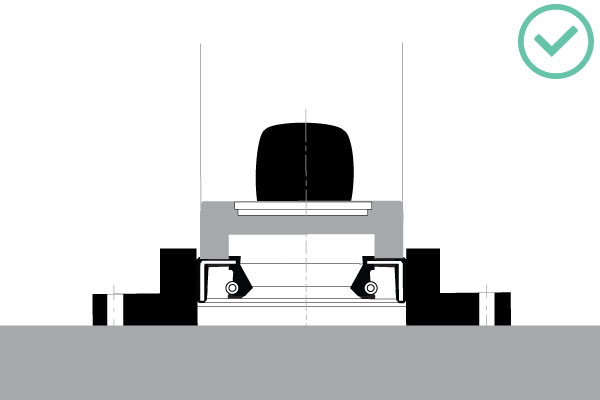

適切な設置方法

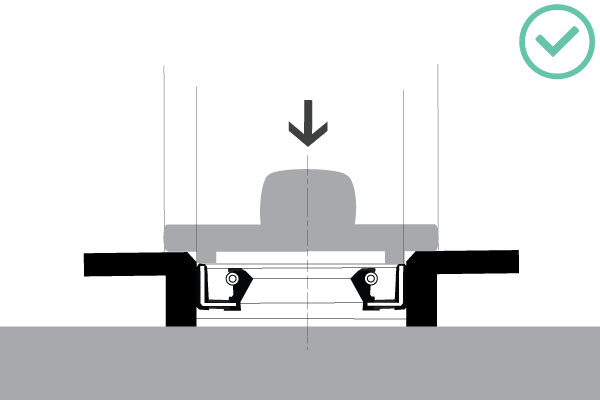

ハウジング表面ストップの取り付け:

- 取り付けツールの底部は、機械加工されたハウジングの面と接触します。

ハウジングストップの取り付け:

- シールの底部はボアの内側の肩部と面一になっています。

表面停止装置の設置:

- 取り付けツールの底部は、機械加工されたハウジングの面と接触します。

シールオーバースプラインの取り付け:

- 取り付けツールは潤滑されており、スプライン、キー溝、面取りされていないシャフトによるシールリップの損傷を防ぎます。

ストライクプレートの取り付け:

- シールを取り付ける際は、シールとボアが適切に位置合わせされていることを確認するために慎重に進めてください。

シャフトストップの取り付け:

- 取り付けツールの底部がシャフトの面と接触します。

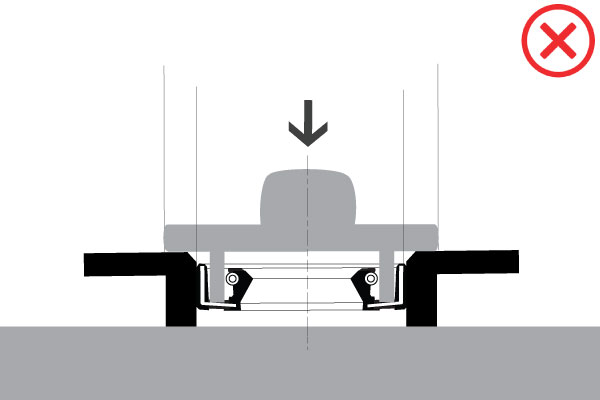

不適切な設置方法

以下に、オイル シールの誤った取り付け方法を説明します。これらの間違いは頻繁に見られますが、業界内では必ずしも理解されておらず、非難もされていません。オイル シールが誤って取り付けられると、へこんだり歪んだりして機能が低下します。取り付けが不適切だと、ボア内で傾き、使用できなくなります。

誤った運転:

シールを取り付ける際には、適切な駆動リングを使用してください。不適切な駆動リングを使用すると、シールが変形したり、位置がずれたりする可能性があります。

小型インストールツール:

取り付けツールの駆動径が小さすぎると、取り付け中にシール部分が変形する可能性があります。

不適切に設計されたインストールツール:

取り付け工具がシールに適していない場合、変形の原因となる場合があります。

位置ずれエラー:

ツールとボアが均等に接触しないと、シールが変形したり、ボア内で傾いたりする可能性があります。その結果、シールされている物質に漏れ経路が生じます。

日本語

日本語  English

English  Español

Español  Français

Français  Português

Português  Deutsch

Deutsch  Italiano

Italiano  Русский

Русский  中文

中文  العربية

العربية  हिन्दी

हिन्दी